Water Well Continuous Slot Screen

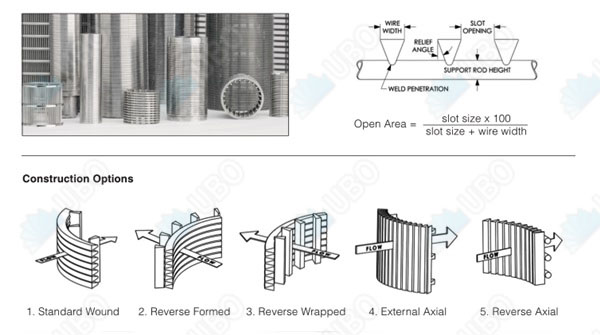

Continuous wire wrap screen are very effective in wells of this type since they can be manufactured with very small slot size and yet still maintain the necessary open area to minimize frictional head loss. A commonly used and effective screen type for water wells uses a continuous slot construction, made by wrapping and welding a continuous length of wire or plastic around vertical rods.

BURGESS “EON” FIBERGLASS CONTINUOUS SLOT WELL SCREEN

COLLAPSE RESISTANCE GUIDE

MAXIMUM COLLAPSE RESISTANCE PRESSURE (psi)

- Wire wrapped screenfeatures continuous slot and permits more water or oil to enter the screen. It can be subdivided into two styles: rod-based screen or wedge wire screen and pipe-based screen. Pre-packed screenis a stand-alone screen for it is previously equipped with packed gravel. Bridge slot screen has a unique construction – bridge slot.

- Flush Threaded: All casing and screen products conform to the accepted ASTM-F480 standard requirements unless alternate specifications are requested. To ensure maximum QA/QC, each casing and screen product is individually packaged in durable moisture resi.

Water Well Screens - Aqseptence

| SLOT SIZE | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 50 | 60 | 70 | 80* | 90* | 100* |

| SCREEN SIZE | |||||||||||||

| 4.5 In. I.D. | 600 | 580 | 560 | 540 | 520 | 500 | 480 | ||||||

| 6.5 In. I.D. | 415 | 400 | 385 | 370 | 360 | 345 | 330 | 315 | 300 | ||||

| 8.5 In. I.D. | 325 | 315 | 305 | 295 | 285 | 275 | 265 | 255 | 245 | ||||

| 10.5 In. I.D. | 260 | 253 | 246 | 239 | 232 | 225 | 218 | 211 | 204 | ||||

| 12 In. I.D. | 225 | 216 | 207 | 198 | 189 | 180 | 171 | 162 | 153 | ||||

| 16 In. I.D. | 185 | 165 | 145 | 125 | 105 | 85 | 65 | 45 | 25 |

* Slot sizes 80, 90 and 100 in 16″ I.D. are manufactured by special order only — “NO WARRANTY”

NOTES:

1. This chart is for quick evaluation of proposed installations. Use only for preliminary assessment.

The above specifications are designed for Burgess “EON” fiberglass continuous slot well screens. All specifications and properties specified above are approximate. Specifications and properties of material delivered may vary slightly from those given above. Burgess Well Company makes no representations of fact regarding the material except those specified above. No person has any authority to bind Burgess Well Company to any representation except those specified above. Final determination of suitability of the material for the use contemplated is the sole responsibility of the Buyer. Burgess Well Company sales representatives will assist in developing procedures to fit individual requirements.

Hebei Shengkai Metal Mesh Co., Ltd. has enjoyed a high reputation among water well screen professionals covering water and oil exploration. Well screen is a key element of sand-control systems, either as an integral component of the gravel pack or as a stand-alone provider of sand control like pre-packed screen.

Comprehensive design for effective water screens and well screens

- Shengkai screen make a full investigation of formation particle size distribution to determine the precise of the well screen. Due to corrosion is another threatening factor of shortening the well screen's operational life, the material of the well screen should be selected.

- Sand control screen is usually working in deep well, the mechanical properties is especially important. Hence, the materials used in well screens should have all the related parameters.

Sand control screens

Continuous-slot Well Screen By HuaDong Screen Co,LTD

- For diverse purposes and applications, slotted liner, continuous slot like wedge wire screen and pipe-based wire wrapped screen, bridge slot screen and perforated casing are provided. All of them use state-of-art technologies to ensure optimum well completions.

- Slotted liner is our star product among sand control screens for its outstanding performance over anti-plugging and excellent mechanical properties. Our company integrates advanced laser cutting process with CNC indexing system. This significantly improves precise slot size and production efficiency as well as significantly reduces the cost.

- Wire wrapped screen features continuous slot and permits more water or oil to enter the screen. It can be subdivided into two styles: rod-based screen or wedge wire screen and pipe-based screen. Pre-packed screen is a stand-alone screen for it is previously equipped with packed gravel. Bridge slot screen has a unique construction – bridge slot. It is characterized by lightweight, lower possibility of clogging and low cost.